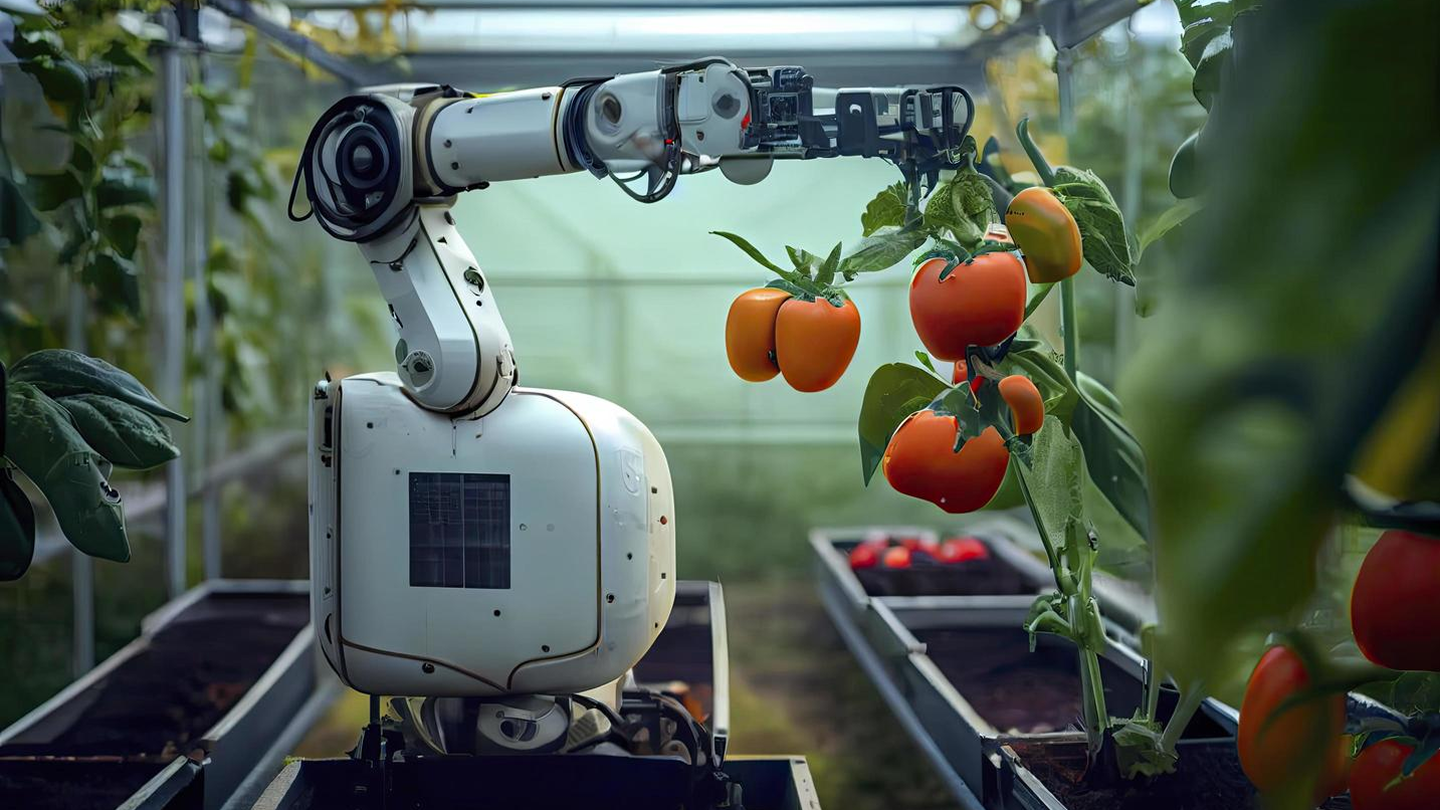

Until recently, machines on farms stuck to grunt work—ploughing, spraying, hauling. But picking fruit? That was sacred ground for human hands. Now, robots with a gentle touch, trained by AI, are taking the lead in the most delicate phase of farming: harvesting.

Agrobot E-Series – The Strawberry Picker of the Future

The Agrobot E-Series is among the world’s first commercially available robots specifically designed to harvest strawberries. Developed in Spain, it uses computer vision and 3D imaging to detect ripeness, and then deploys 24 robotic arms—yes, 24—to pick only the fruit that’s ready.

Advantages:

- Touch-sensitive grippers that gently remove berries without bruising

- Selective harvesting based on AI ripeness detection

- Operates continuously in greenhouses and open fields

Key Features and Capabilities

- Advanced Vision Systems: The E-Series utilises integrated colour and infrared depth sensors to assess fruit ripeness in real-time, ensuring only mature strawberries are harvested. Agrobot: Agricultural Robots

- Gentle Harvesting Mechanism: Each robotic arm is designed to grip and cut the stem without contacting the fruit directly, minimising damage and preserving quality.

- Adaptable Configuration: The platform’s flexibility allows it to fit into various farming setups, from open fields to greenhouses.

- Robust Construction: Built with stainless steel and high durability aluminium, the E-Series is engineered to withstand diverse climatic conditions and the rigours of field operations.

Limitations:

- Primarily suited for high-density rows and controlled environments

- Price not publicly disclosed, but cost-effectiveness depends on scale

Use Cases:

Agrobot has tested units in California and Mexico, where labour shortages and high demand for soft fruit harvesting align perfectly with its strengths.

Why These Robots Matter

Labour shortages are hitting agriculture harder than most sectors. Fruit and vegetable picking is time-sensitive, repetitive, and physically taxing—all of which make it ideal for automation.

These AI-powered harvesters don’t just reduce dependence on seasonal workers. They:

- Operate with greater consistency during long harvest windows

- Collect real-time yield data to help farmers plan better

- Improve food safety by minimizing human contact during harvest

- Reduce wastage and bruising, especially with soft fruits

How Much Do They Cost?

Pricing varies based on size, scope, and integration – Agrobot E-Series comes at a custom pricing based on the farm size. While the upfront investment is significant, many farms recover costs through labour savings and yield optimisation within 2–3 seasons.

The Honest Truth: What Still Needs Work

Despite impressive capabilities, robotic harvesters aren’t flawless. Challenges include:

- Adapting to diverse plant structures and fruit visibility

- Environmental variability (lighting, mud, temperature) affecting AI sensors

- Steep learning curve for integrating these systems into traditional workflows

And yet, these machines are improving fast—with newer models boasting better object detection, weather resilience, and multi-crop flexibility.

Not Replacing Farmers, Just Reimagining the Role

Harvesting robots won’t replace farmers. But they will take on tasks that strain human bodies and burn up labour budgets. In return, farmers gain more time to focus on strategy, sustainability, and stewardship—the things that really matter. The integration of robotics like the Agrobot E-Series into agriculture signifies a transformative step towards sustainable and efficient farming practices. As technology continues to evolve, such innovations will play a crucial role in meeting the growing global food demands.

Your next harvest could be smarter, faster, and more sustainable—start your automation journey with our experts today.