The global fruit industry is facing a pivotal transformation. Between rising labor shortages, increasing consumer demand, and the growing need for sustainability, traditional harvesting methods are being replaced by advanced robotic harvesters that can pick, sort, and optimize yield faster and more efficiently than ever.

This article explores how cutting-edge fruit-picking robots are already being used in the field, and how they’re reshaping orchard economics—from branch to box.

Fruit-Picking Robots Making a Difference

1.FFRobotics – FFRobot Harvester

- Manufacturer: FFRobotics

- Best For: Apples, citrus, pomegranates

How it Works:

The FFRobot Harvester is equipped with 12 robotic arms, each fitted with soft, flexible grippers or suction mechanisms that mimic human hand movements. Using computer vision and AI, the robot detects the ripeness of each fruit and carefully removes it from the tree without bruising.

Key Capabilities:

- Up to 10,000 picks per hour

- Multi-crop support: Adjusts to different fruit types

- Non-stop harvesting: Operates in daylight and darkness

- Integrated with data platforms for crop analytics

Limitations:

- Requires orchards to be robot-friendly (specific pruning styles)

- Initial purchase cost is high (estimated ~$300,000 per unit)

- Not ideal for steep or irregular terrain

Field Results:

A 2023 pilot program in Washington State, led by the Washington Tree Fruit Research Commission and reported in the Good Fruit Grower Journal, found that FFRobotics’ system reduced seasonal labor needs by up to 50% and improved harvesting consistency across day and night operations. According to the study, ROI for large orchards could be achieved in 3.5 to 4 harvest seasons, factoring in labor cost savings and reduced fruit bruising.(source)

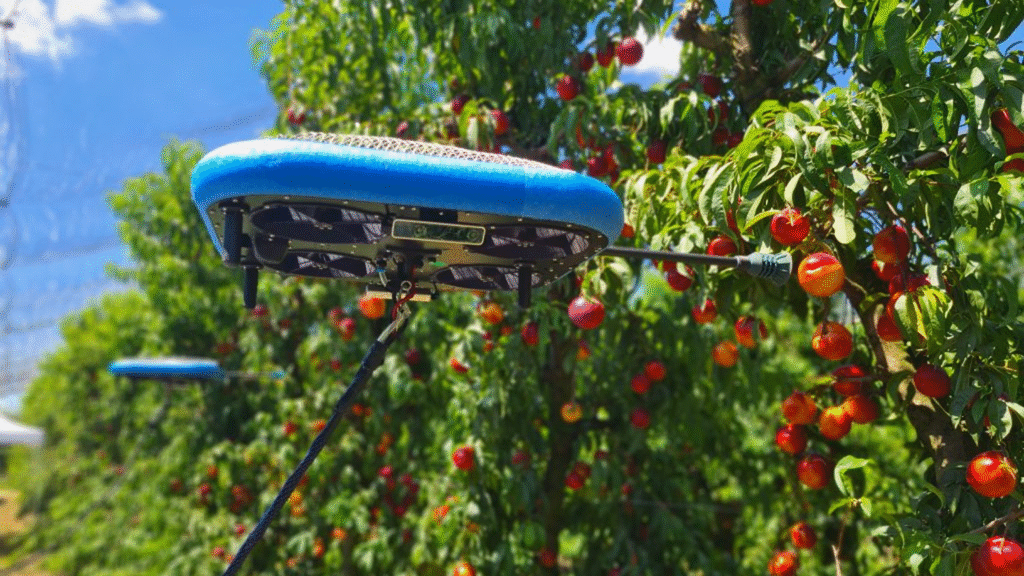

2.Tevel Aerobotics – Flying Autonomous Robots (FARs)

- Manufacturer: Tevel

- Best For: Apples, nectarines, plums, peaches

How it Works:

Tevel’s FARs are AI-powered drones tethered to a ground vehicle. Each drone is equipped with a computer vision system and suction-based picking tool. Drones detect, locate, and harvest only ripe fruit with gentle precision, reducing waste and bruising.

Key Capabilities:

- 6–8 drones operate per vehicle simultaneously

- Real-time ripeness recognition

- Lightweight and non-intrusive

- Designed to complement human labor, not fully replace it

Limitations:

- Sensitive to weather conditions (especially wind)

- Needs connectivity (LTE or Wi-Fi) for real-time cloud processing

Field Results:

In 2022, Tevel’s FARs were deployed in commercial orchards in Italy, focusing on apricot harvesting. According to a report by Future Farming, the system was set to start harvesting apricots in Italy from June 2022. Additionally, Tevel’s technology has been recognized for its innovation in the field of autonomous harvesting. The company was named a winner in the ‘Top-10 New Product’ competition at the World Ag Expo in Tulare, California. These deployments and recognitions underscore Tevel’s commitment to advancing autonomous fruit harvesting solutions.(source)

Global Deployment in Action

Here’s how growers are integrating these robots:

- USA (Washington): Apple growers use FFRobots during peak season when labor is tight, especially for day-and-night shifts.(source)

- Spain (Catalonia): Tevel’s drones were used in stone fruit orchards to supplement a reduced human workforce. (source)

- New Zealand: Mixed fleets using both ground-based and aerial harvesters are becoming the new norm for export-quality apples. (source)

Benefits vs. Drawbacks

| Feature | Benefits | Challenges |

| Precision Picking | Higher fruit quality, less bruising | Slower on difficult tree geometries |

| Reduced Labor Dependency | Cost savings, fewer staffing issues | High capital investment |

| Data Collection | Better forecasting and yield planning | Requires digital literacy for operators |

| 24/7 Operation | Extended harvest windows | Some terrain or weather limitations |

What’s Next in Fruit Robotics?

Fruit-harvesting robotics are evolving rapidly. Expect to see:

- Full fleet automation: Transport + harvest robots working in tandem

- AI-assisted forecasting: Predict ripeness, yield, and optimal harvest times

- Plug-and-play integration: Robots compatible with farm ERP systems

- Cost reductions as adoption scales

In development:

Companies like AgXperience Robotics and Octinion are planning modular robots that can adapt to farm size, crop type, and budget constraints—ideal for small-to-mid-sized orchards.

Need Help Choosing the Right Harvester?

Reach out to us at SmartHubShopper.com for curated recommendations based on your orchard’s specific needs.